Biography

Hello 👋 This is ZiYu Lin (林子愉).

I am ZiYu Lin, an environmental scientist with a deep passion for sustainable urban water management and ecosystem health.

With a PhD in Applied Environmental Science & Engineering from Kyung Hee University, specialize in optimizing urban drainage systems, analyzing water pollution, and assessing biodiversity. My work has involved high-impact projects and extensive research, particularly in developing water quality prediction models and promoting environmental sustainability.

I am also fluent in multiple languages and proficient in programming, I am dedicated to bridging the gap between research and real-world environmental solutions.

Feel free to look at my publications, recent post, and my full CV in this webpage.

Thanks for visiting my webpage!

- Urban Drainage System.

- Water Pollution Analysis.

- Water Quality Prediction Model Development.

- Water Ecosystem Health Assessment.

- Biodiversity Analysis.

PhD in Applied Environmental Science and Engineering, 2025 (expected)

Kyung Hee University (Global), KR

MSc. in Applied Environmental Science and Engineering, 2022

Kyung Hee University (Global), KR

BSc. in Environmental Engineering, 2018

Shandong University of Science and Technology, CN

Featured Publications

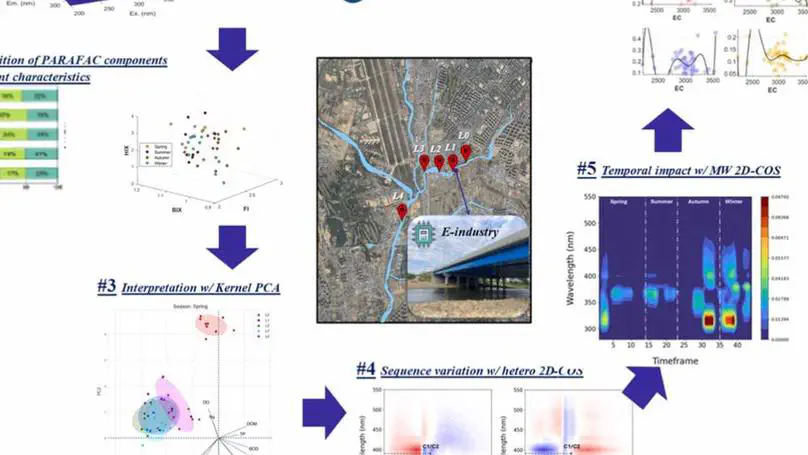

Industrial activities often disrupt the natural equilibrium of water bodies, with discharged wastewater introducing dissolved organic matter (DOM) and pollutants. This study investigated the water quality along a riverine system subjected to heavy industrial influence by collecting samples from distinct points at before, during, and after industrial discharge across four seasons. By employing EEM-PARAFAC, four fluorescent components were identified at the discharge point including C1 (microbial/ terrestrial humic-like), C2 (anthropogenic humic-like materials), C3 (microbial humic-like), and C4 (wastewater/nutrient enrichment tracer). Specifically, C2 and C4 which contained wastewater and anthropogenic-like material are not found at the pre-pollutant point. Additionally, fluorescence characteristics parameters such as FI, HIX, and BIX are analyzed. Kernel Principal Component Analysis was employed to elucidate the non-linear relationships inherent in the data that able to covered up to 97 % of the data variance, offering nuanced insights into complex behavior of water characteristics across seasonal variations. Two-dimensional correlation spectroscopy (2D-COS) was further employed to evaluate the sequence variation of DOM components and further identify the temporal effect across season with moving window 2D-COS. The sequence order of the DOM fractions was identified as C2→C4→C1→C3 by following the Noda’s rule. In order to understand the interactions between the water characteristics and the DOM components, an empirical polynomial regression model is developed with an average MAPE of 2.2 %. The interaction between DOM-related parameters was identified using structural equation modeling. These findings underscore the dynamic nature of DOM composition under industrial influences considering the spatial-temporal impact.

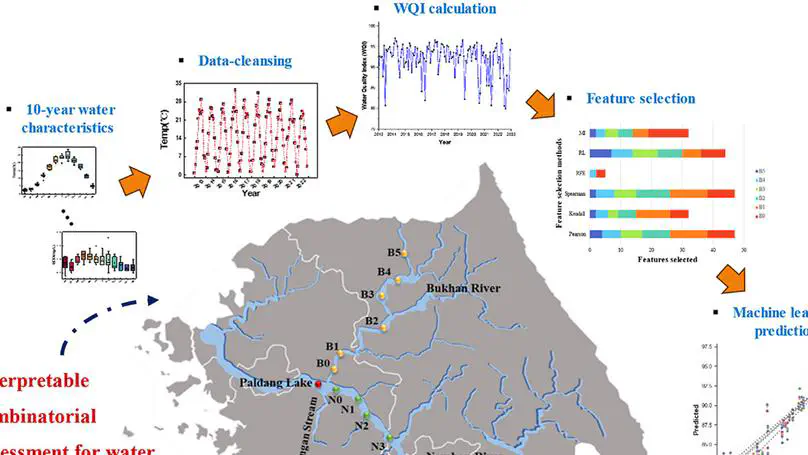

Water security remains a critical issue given the looming threats of industrial pollution, necessitating comprehensive assessments of water quality to address seasonal fluctuations and influential factors while formulating effective strategies for decision makers. This study introduces a novel approach for evaluating water quality within a complex riverine zone in South Korea, Han River that encompasses five river streams situated at each junction of North and South streams (including Gyeongan Stream) that ultimately leading towards Paldang Lake. By utilizing the monthly water characteristic data from the year 2013–2022 across 14 different locations, the significant seasonal trends and potential influences on water quality are identified. The water quality here is calculated with the proposed method of sub-index water quality index (s-WQI). A combinatorial prediction approach of s-WQI for each location is conducted through a collective of data preprocessing approaches including Hampel filtering and feature selection in prior to the machine learning predictions. In return, light gradient boosting (LGB) is the most accurate predictor by outperforming other prediction algorithms, especially through LGB-Pearson and LGB-Spearman combinations for North and South stream intersections, and LGB-Pearson for Paldang Lake. To further evaluate the robustness of this evaluation and extending the results to a foreseeable scenario, a seasonal based Monte-Carlo Simulation with 10,000 attempts targeting the water characteristic distributions obtained from each location considered are carried out to identify the risk bounds within. The results are further interpreted with SHAP analysis on identifying the contributions of each water characteristics towards the water quality through local and global spectrum. This research yields practical implications, offering tailored strategies for water quality enhancement and early warning systems. The integration of AI-based prediction and feature selection underscores the transformative potential of computational techniques in advancing data-driven water quality assessments, shaping the future of environmental science research.

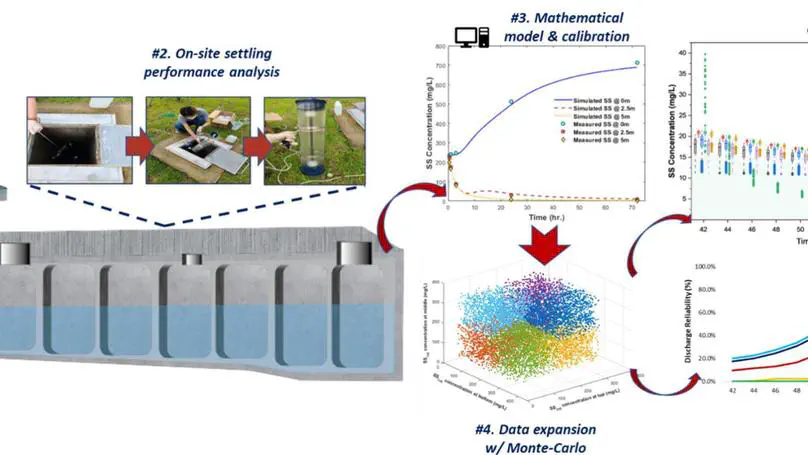

Nonpoint source contamination from early stormwater runoff in the urban area has been frequently reported, and a comprehensive urban stormwater treatment system in high population density location is essential. However, there is an absence of a comprehensive discharge protocol for the settling tank that leads to inefficient treatment process with a non-adaptive practice that fixing certain discharge period. A case study in a large-scale urban settling tank located at Y-city, South Korea is considered to validate the discharge protocol proposed. The stormwater is first analyzed with its respective characteristics from various interception facilities, which act as buffers before entering settling tank. Thereupon, homogenous stormwater entered from multiple interception facilities is collected accordingly from the settling tank to assess the settling performance by measuring the suspended solid (SS) concentration in different timeframes. A mathematical model targeting the settling tank is then developed and further calibrated at different settling tank layers across different settling periods with multi-objective genetic algorithms based on the settling parameters considered. An uncertainty analysis is then conducted due to the relatively small dataset collected by incorporating 10,000 attempts of Monte-Carlo simulation, varying the SS concentration at different layers in the settling tank. As a result, discharge time for the top and middle layer by obeying the discharge limit falls at the 18th and 58th hour from the initial stormwater entry to the settling tank. This study successfully demonstrated the approach on identifying optimal discharge protocol for urban settling tank based on the initial SS concentration under limited data.

Recent Posts

Recent Publications

Contact

- ziyulin96@gmail.com

- Suwon, 60439